Hoisting the condenser and securing it into place has been the trickiest part of still assembly. As such it has been nicknamed the “Saturn V”. While the condenser may look visually smaller than the pot in size, it is the heaviest piece to lift and place. This is due to the enormous lengths of tubing within the copper cylinder designed to rapidly cool vapours coming from the pot still.

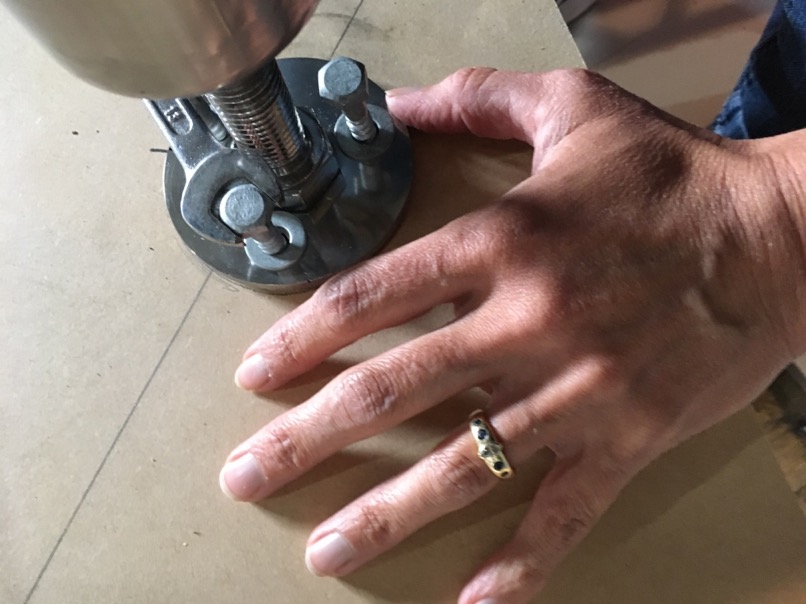

As a process, we began the next steps of assembly with the line arm. Attaching this first meant we could use it as an important point of reference. The line arm supports built by Gareth, were designed to hold the line arm at a 20 degree angle and hinged to allow movement backwards and forwards to easily bolt it to the neck of the still. Once up, it allowed us to line up the condenser perfectly.

Resting in its makeshift rope hammock, the condenser could be raised using the forklift. Safety ropes, forklift in position and with everything secured, the column slowly rose off the floor and into position without a hitch.

As things were so carefully planned there was the expectation that it would work but there was still a collective sigh of relief after this top heavy object gently touched down and landed perfectly in place. Whew! Now for the final polish!

We wondered how you did it. Saturn V seems an appropriate name.