Three weeks in to learning the brewing and distillation process and I think I am slowly getting a headset on the brew day. In the process of brew learning 101, I have three important tips for working with hoses:

- Spanners are very handy to loosen off hoses attached by blokes.

- Heat proof gloves are a must when undoing hot metal on the ends of hot side brew hoses.

- Most importantly…. remember when cleaning hoses out with a high pressure gun to open the keystone valve (tap) on the other end or you will be well and truly soaked! (the water has nowhere else to go except up and out like a fountain)

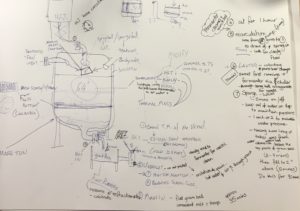

The brew house here at the Fleurieu Distillery is compact and the vessels are connected with movable hoses as needed rather than permanent stainless steel plumbing. It does make it flexible but in order to get the set up right for either brewing or a whisky wash there is so much to remember. That’s where a good diagram, labelling of hoses and methodical recording of process comes int o play.

o play.

This was the initial diagram with detailed explanations late Saturday night as the hose movement and pump connections were doing my head in after 2 brew days. Tomorrow will be my third brew day under Pete’s direction so I am hoping after labelling the hoses again and having a diagram in hand my efficiency in the brew house will markedly improve. Here goes…